Innovations in process technologies are contributing to the sustainable and efficient production of battery electrodes. For example, DRYtraec® replaces today's solvent-based electrode coating processes and drastically reduces energy and space requirements. Further process innovations are needed to introduce new, higher-performance battery materials. For example, we are developing solutions along the process chain for the production of lithium metal batteries. Our goal in each case is the transfer of technology to industrial use.

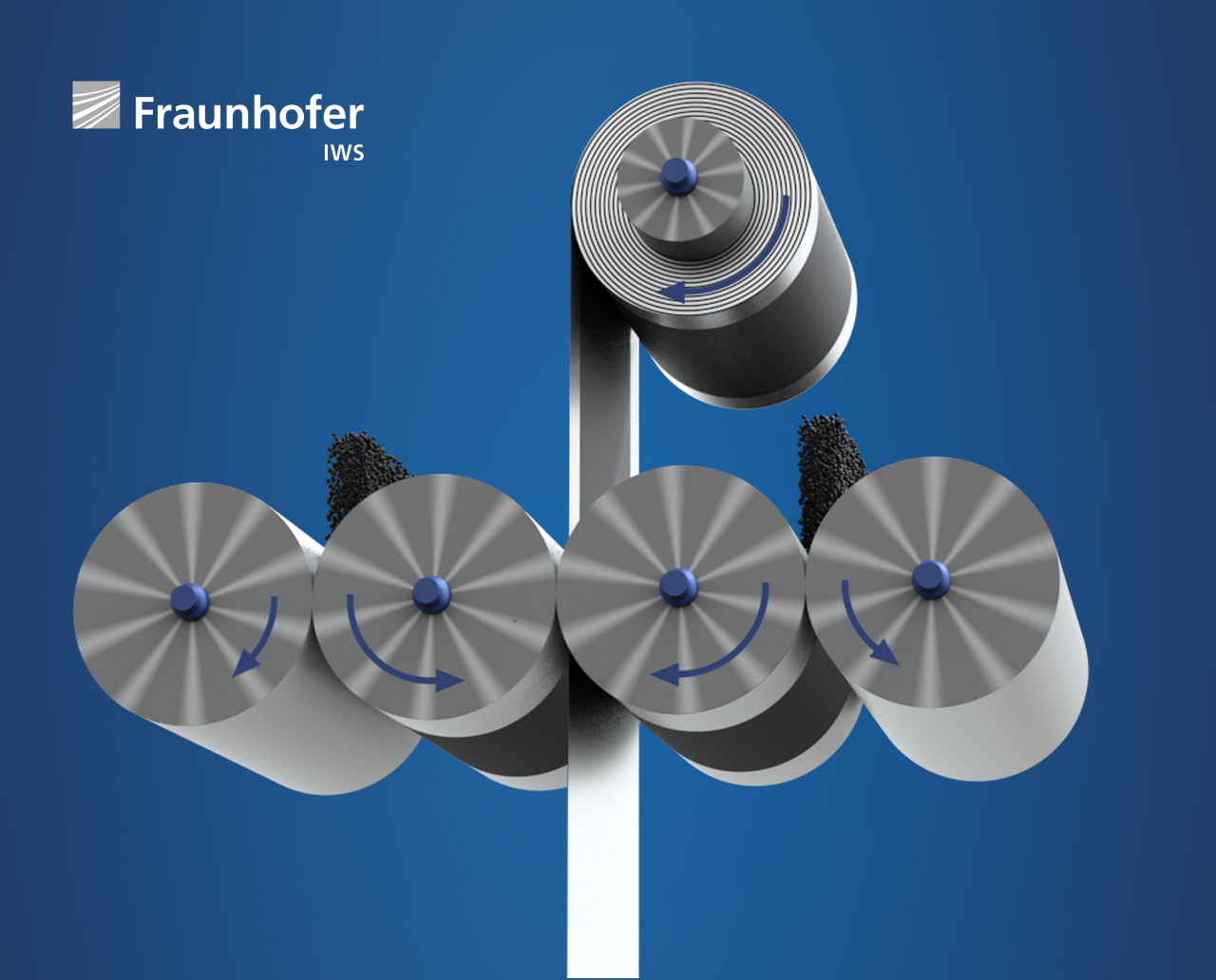

DRYtraec®

The DRYtraec® coating process developed at Fraunhofer IWS allows the dry production of battery electrodes without toxic organic solvents or water. This process eliminates the space and energy intensive drying step of conventional wet chemical coating processes. Fraunhofer IWS offers a holistic technology platform to research dry-coating technology and prepare it for transfer to industrial applications.

Lithium Metal Anodes

Lithium metal anodes are considered a key element for the battery systems of the future. They enable the maximization of energy density in terms of both cell volume and mass. One challenge is the scalable production of thin lithium layers. Fraunhofer IWS has developed a coating process that allows to produce lithium layers with a thickness of only a few micrometers. The key innovation lies in a lithiophilic surface that enables low cost and homogeneous deposition of thin films of molten lithium on metallic substrates. The equipment at Fraunhofer IWS allows double-sided coating of thin current conductor foils in a roll-to-roll process.

Carbon Coatings on Powders by Means of Chemical Vapor Deposition (CVD)

Carbon layers with a thickness of just a few nanometers can decisively improve the properties of powdered battery active materials. A defined, conductive interface is created, which positively influences the interaction with the electrolyte system or other electrode components. Especially anode materials like graphite, hard carbon and silicon benefit from this surface modification and formation losses can be drastically reduced. Fraunhofer IWS offers experiments on carbon coating by CVD and the evaluation of the materials in battery cells.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS