Structural mechanical cathode adaptation on silicon- and lithium-based anode materials (KaSiLi)

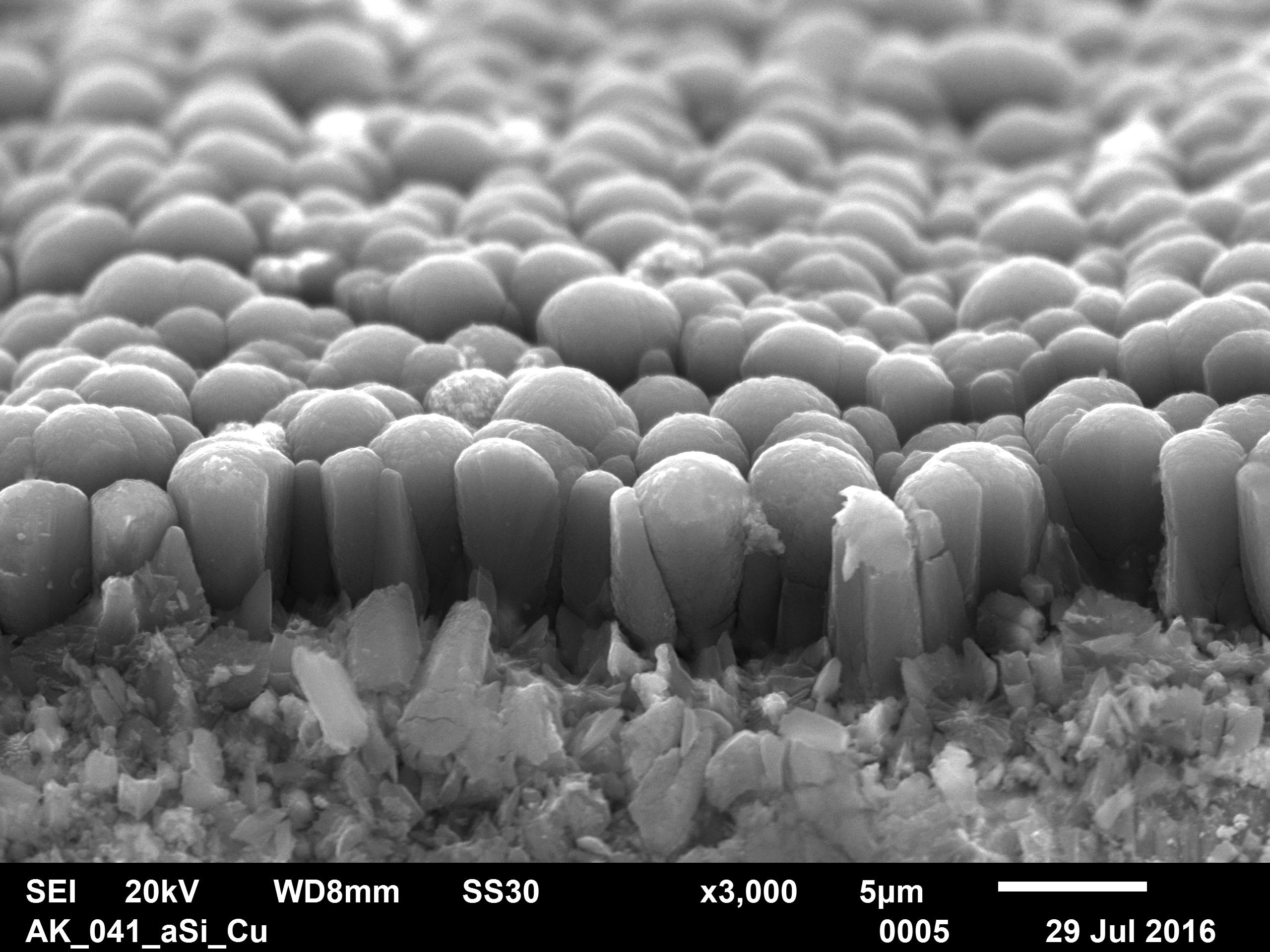

New thin-film electrodes made of silicon and lithium for the “Research Fab Battery”

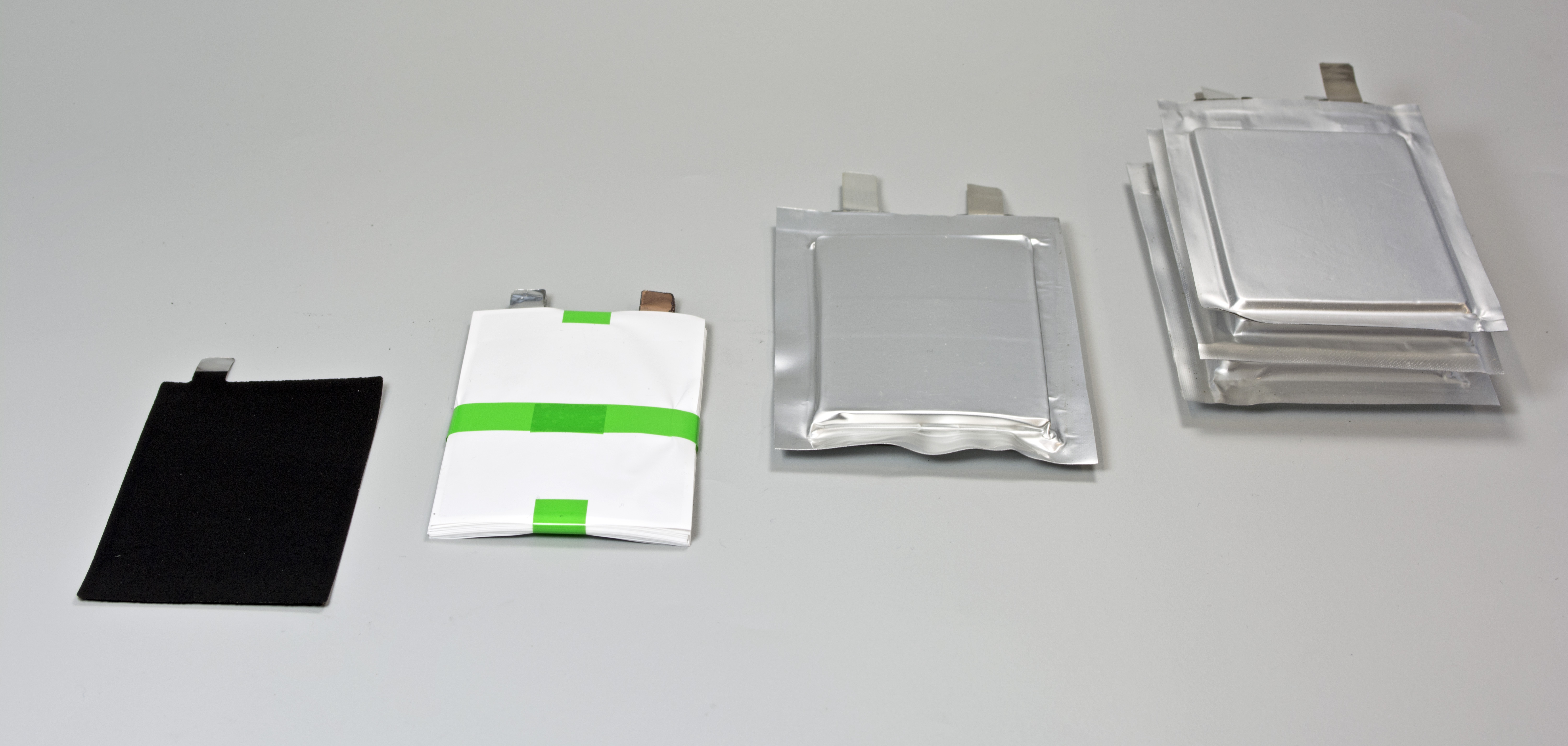

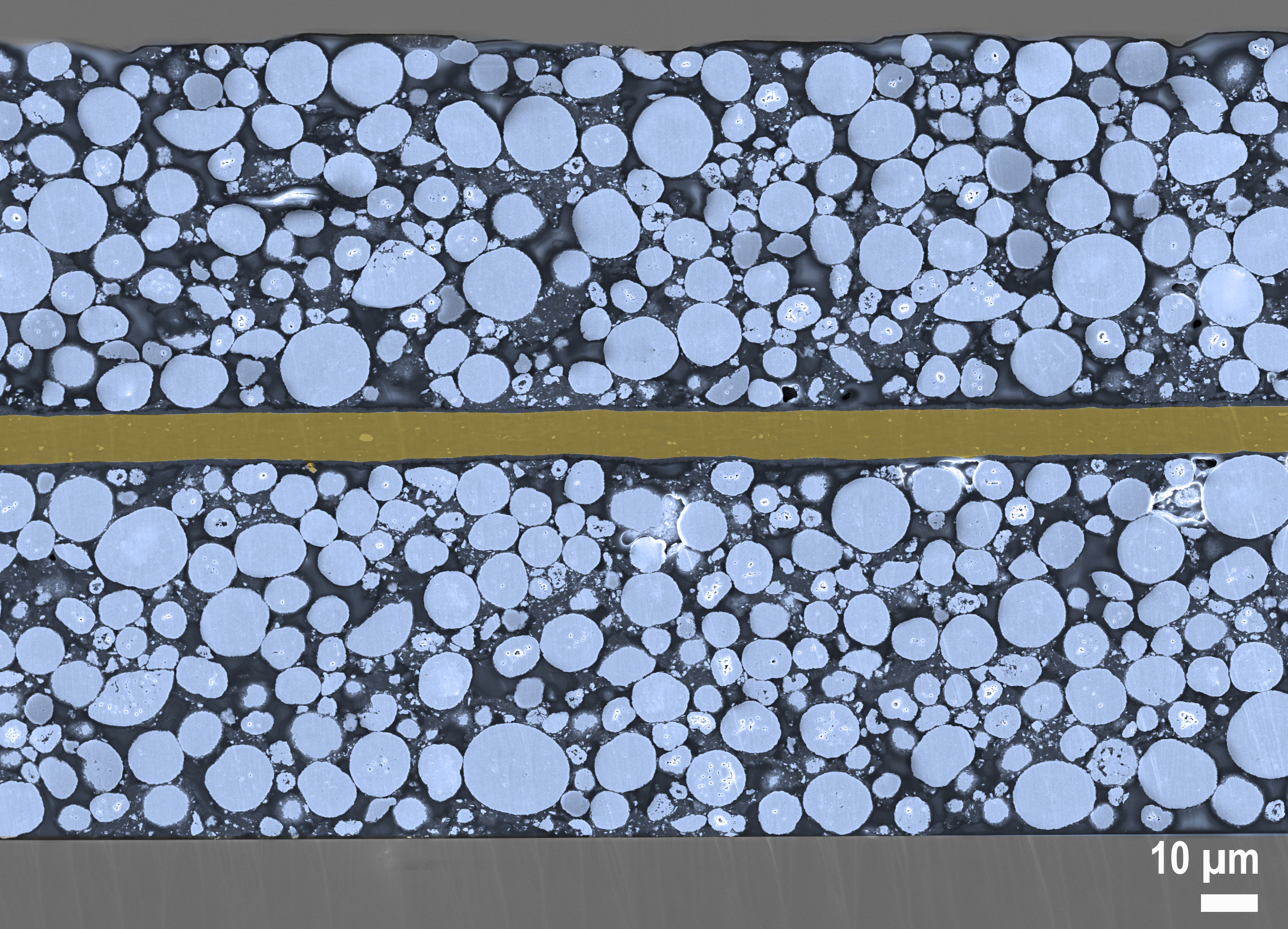

The project's overall objective is to develop high-energy cells (Li-S and LIB) based on lithium and silicon anodes increasing the energy density compared to conventional lithium-ion cells and minimizing the volume change during cycling.

The developments focus on high-energy cells based on silicon and lithium anodes, which allow an increase of the volumetric energy density of up to 65 % compared to conventional lithium ion cells. However, the significant charge-state dependent volume changes of these materials on the microscale are transferred to a (macroscopic) change in the thickness of the cells and thus lead to major challenges for the cell integration into battery systems. The present project addresses these challenges with innovative approaches to reduce the volume changes.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS