Precise temperature calibration for laser-based heat treatment processes

Precise temperature calibration is of utmost importance to the quality of numerous short-term heat treatment processes. At the Hannover Messe HMI (hall 6, booth B33), taking place from April 8 -12, 2013, Fraunhofer IWS engineers will present novel temperature measuring devices for laser hardening processes, which can be calibrated and recalibrated by the operator directly and on-site.

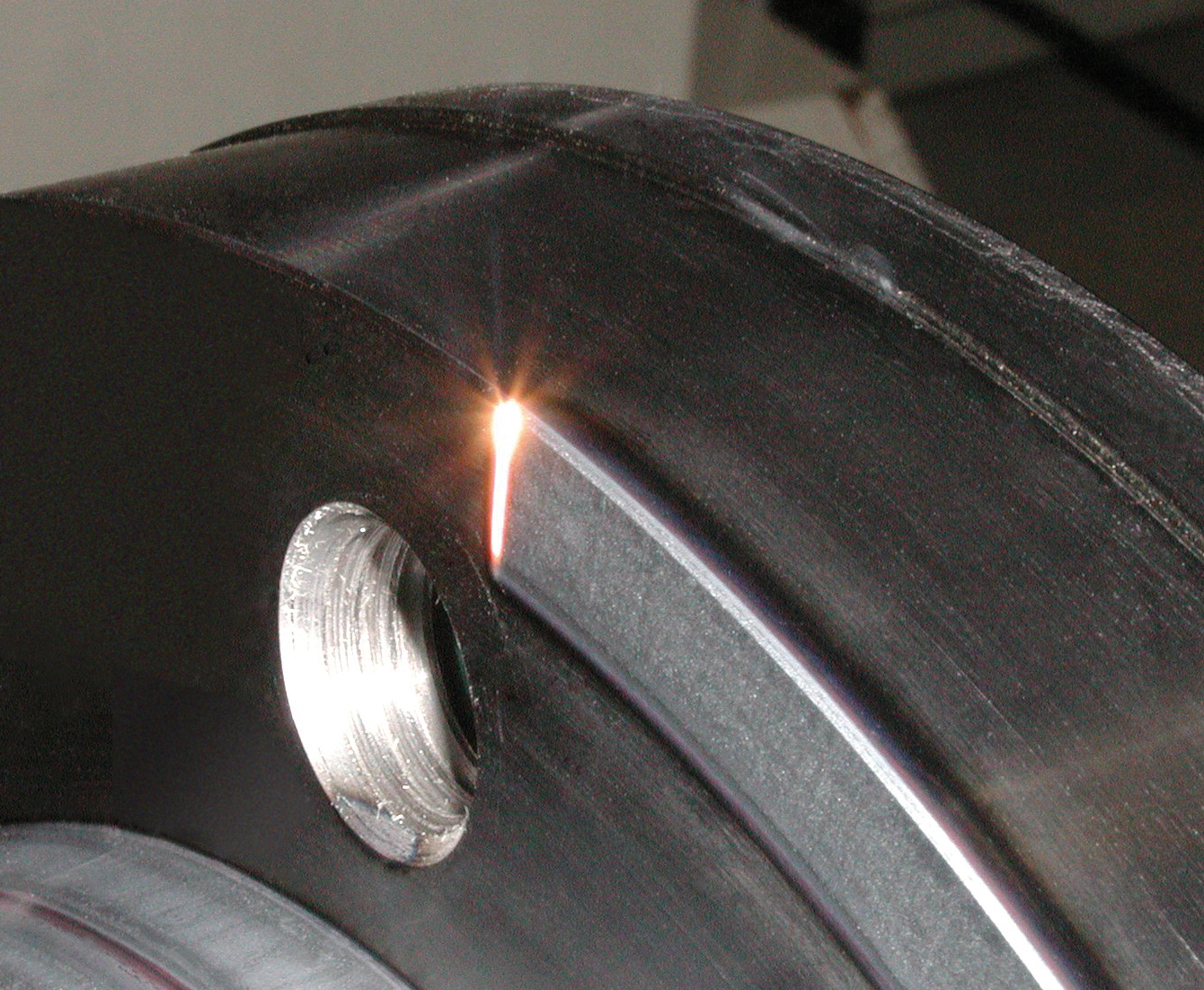

The applied non-contact temperature measuring devices, such as pyrometers and camera systems, are in most cases, mechanically, optically and electrically completely integrated in complex manufacturing systems. Thus the initial and final calibration must occur directly on-site at the laser hardening equipment. A significant problem is often the unknown attenuation of the temperature signal caused by protective windows, lenses or other optical components. This can even be significantly effected during operation due to contamination.

Temperature measurement devices, based on fixed-point cells presently enable the most accurate calibration procedures. These fixed-point cells are usually small graphite blackbody radiators, filled with highly-pure metal alloys, of which the melting point is known. If the fixed-point cells are furnace-heated close to the melting point of the metal alloys, precise calibration points can be determined through the emerging temperature plateaus during the melting and solidification phases.

Principally, classic fixed-point cells achieve highly precise accuracies and calibration-uncertainties are typically less than 100 mK. However, the limited flexibility and mobility of the furnaces and the long cycle times between heating and cooling are very disadvantageous.

The use of a mobile compact inductive heating source was the key to solving this problem. Together with the scientists of the Physikalisch-Technische Bundesanstalt (PTB), Fraunhofer IWS engineers designed, built and tested a mobile inductively heated fixed-point device for the calibration of pyrometers and thermal cameras. The fixed-point cell can be heated to 1500°C within few minutes. Several measurement cycles to establish calibration points can be performed within an hour.

This calibration procedure, operating at the high temperature range of 1000 to 1500°C, has been developed in cooperation with several other European research and testing institutes. The European Union and EURAMET partner countries are funding the”HiTeMS” project. (http://projects.npl.co.uk/hitems)

Apart from this novel calibration technology the Fraunhofer IWS Dresden will present many new industrial applications for laser hardening and build-up welding processes as well as system technology components for both at hall 6, booth B33 in Hannover. Furthermore visitors may receive information about thermally sprayed heat-conductor coatings, laser-welded crash components and about IWS` comprehensive know-how with respect to materials and component characterizations.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS