Additive manufacturing – Competence in materials and production technology

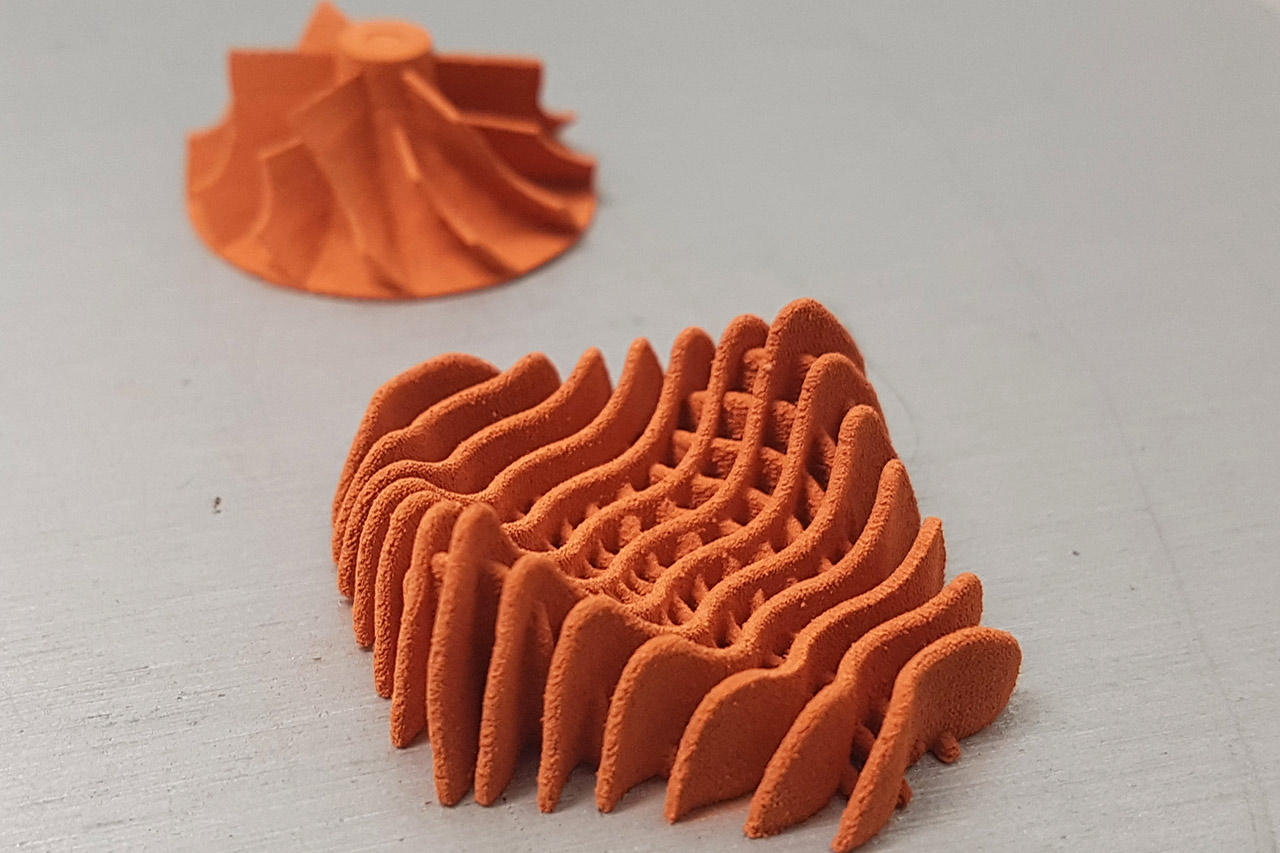

At the Additive Manufacturing Center Dresden (AMCD), which is operated by Fraunhofer IWS and TU Dresden as a joint competence center, the researchers develop multiprocess material and manufacturing solutions for innovative products in order to realize applications in aerospace, energy and medical technology, tooling and mechanical engineering as well as automotive engineering.

With AGENT-3D, the experts at AMCD are also coordinating one of the largest European research projects on additive manufacturing. Together with 120 network partners, this rapidly growing technology field is being pushed forward into an industrially mature production process.

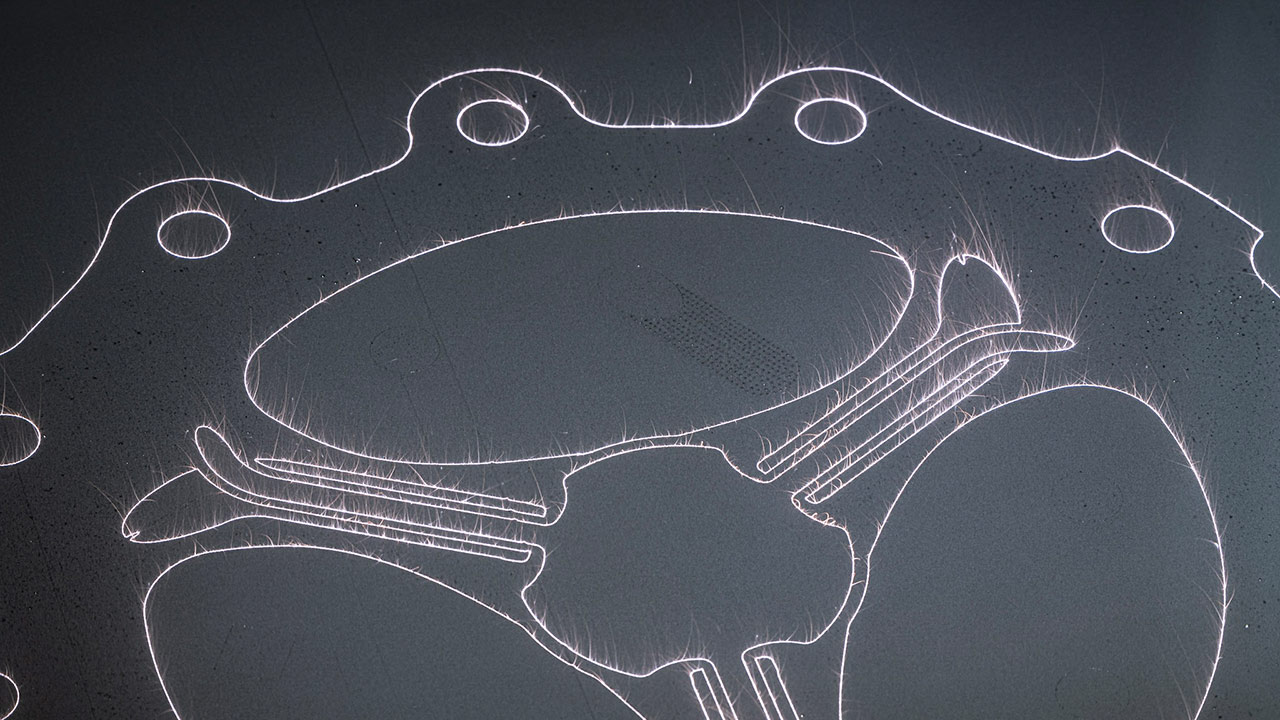

In a rapidly developing high-tech sector, the AMCD offers an ideal networking platform for both industry as well as university-based fundamental and application-oriented research. In cooperation with industry and research partners, the aim is to eliminate existing process restrictions and to define and create a framework for standardization, process reliability and quality assurance.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS