Breakthrough on the way to "artificial muscles" – a new technology platform delivers excellent results

Dielectric elastomeric actuators (DEA's) represent a tremendous hope for the development of artificial muscles. Furthermore they can potentially serve as a viable, economically and environmentally friendly alternative to electric motors, pneumatics or hydraulic drives. In general the DEA´s are very simply constructed. An electrically insulating dielectric, made of elastomeric material, e.g. elastic bands or silicone, is placed in between two metal coated surfaces (electrodes). If an electrical voltage is applied, an electrostatic pressure will be generated, which forces the elastic material to stretch.

Looking for an intelligent solution

Exactly this combination of a metal with an elastomer is the reason why, hitherto, the technological application of DEA's has remained so unsatisfactory. The hardly stretchable, electrically conductive metal layers tear very quickly and are thus destroyed. Up to now, it has only been possible to address the problem in a very cost-ineffective and highly complex way. Addressing this challenge, Fraunhofer IWS and IKTS scientists teamed up with TU Dresden researchers and focused their efforts on one decisive question: Is there a radically new, but simple and technologically sustainable method to solve all these obstacles in one swoop?

One material for all applications

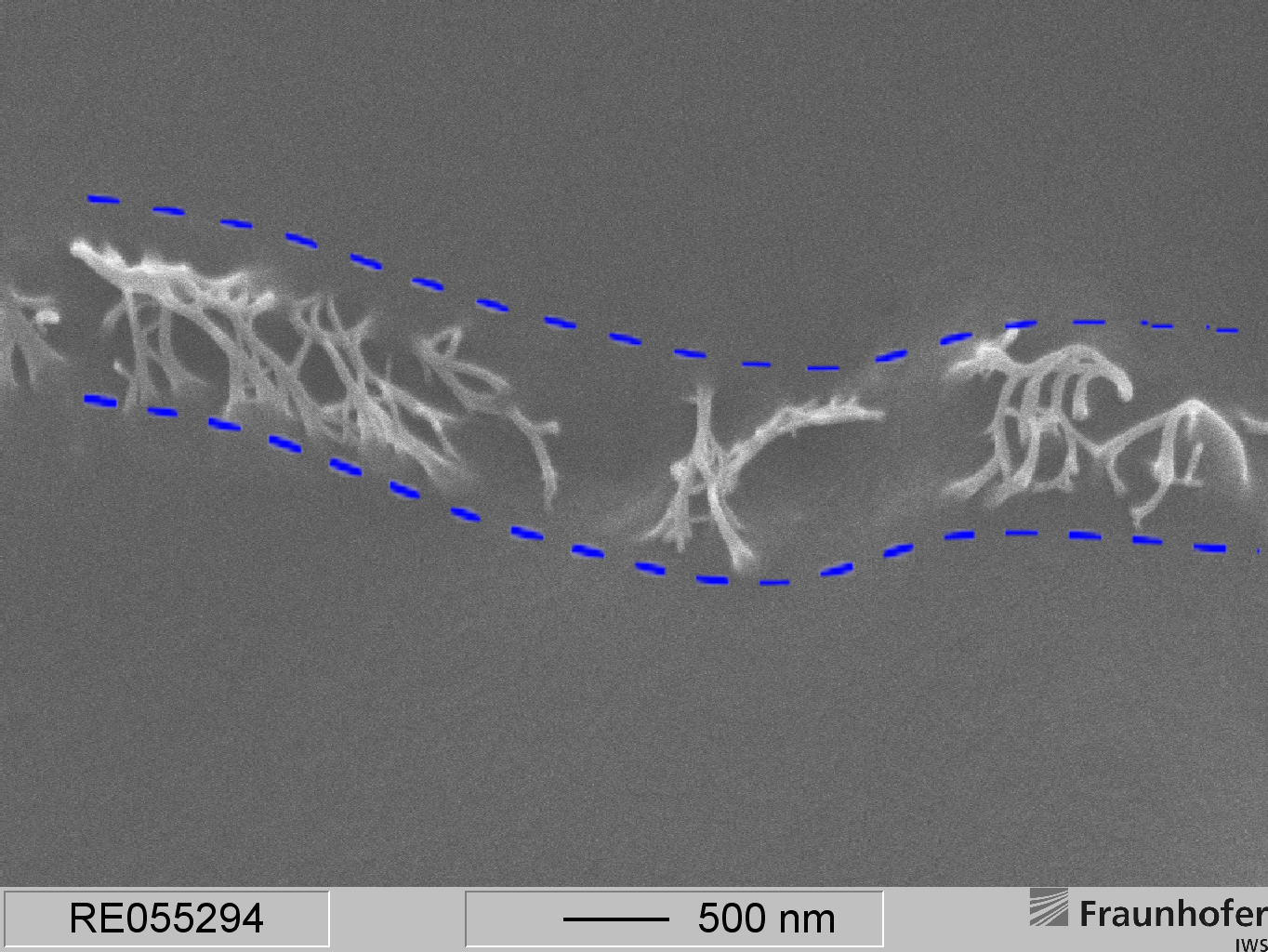

The idea is strikingly simple: substitute the metal coating by an electrically conductive elastomeric coating. In this way it should become possible to avoid the incompatibility between metallic electrodes and dielectric silicone. Up to now, however, there is no commercially available elastomer, which can be both electrically insulating and conductive at the same time. By means of a trick, the Dresden scientists were successful to create exactly such an elastomeric material, which meets all the mentioned requirements. They added tiny amounts of conductive carbon nano-fibrils to an elastomer. The now electrically conductive material still had nearly the same stretching properties as the electrically insulating material. This conductive elastomer, applied on top of the insulating elastomeric material, formed a nearly monolithic sandwiched body that did not deterioate mechanically and electrically in tests even after millions of stress-strain cycles.

Simple production and high performance

Due to this revolutionary success, the nextstep was to design technically applicable actuators. Within shortest time andusing industrial standard technologies, the team succeeded in constructing dielectric actuators. They consist of many alternating conductive and insulating elastomer layers, each of them only 0.03 mm thick. It could be proven that thick film and screen printing techniques as well as large-area roll-to-roll technologies are well applicable. The test results of a multilayer ring actuator, consisting of 11 active layers and an active area of 465 cm2, are very promising. By actively operating the actuator, the scientists found linear strains within the single digit percentage range while at the same time getting remarkable forces of appr. 100 N. Even after 140 000 runs the ringactuator remains in good shape and is still ready for use.

Outstanding chance as platform technology

All in all, the successfully developed materials and coating techniques are most promising and cost-saving approaches,which foreseeable will enable the use of actuator-active structures in many different business fields. Furthermore their application can be imaged in neighboring areas such as sensor technology or Energy Harvesting.The presented results have been achieved within the framework of the project "Candela". This R&D project has been funded by the BMBF (Förderzeichen 13N10 661 and 13N 10660) and by the Projektträger VDI Technologiezentrum GmbH, VDI-TZ, EINS, Nanotechnologie.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS