imanto® - imaging tools

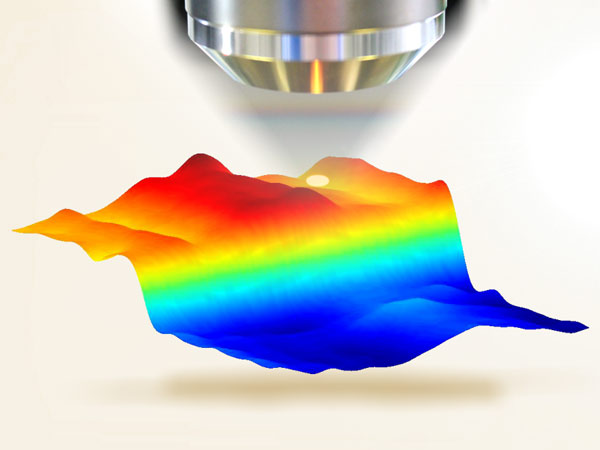

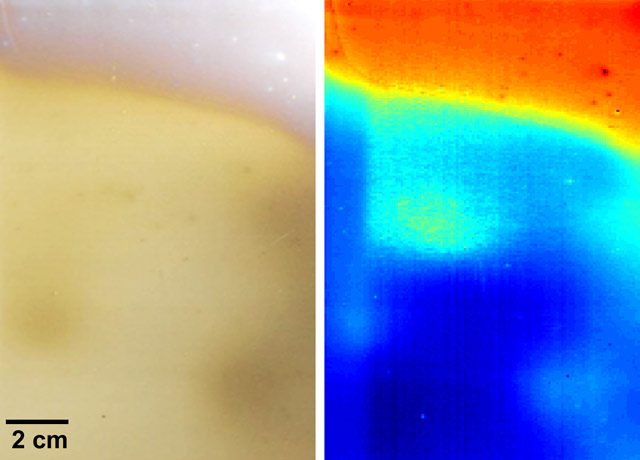

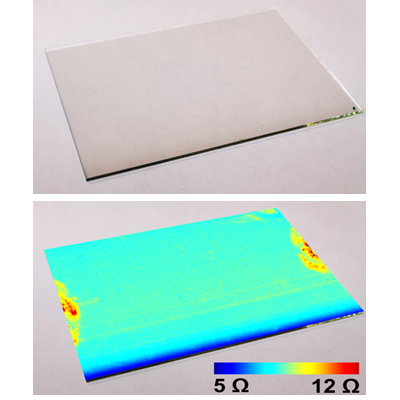

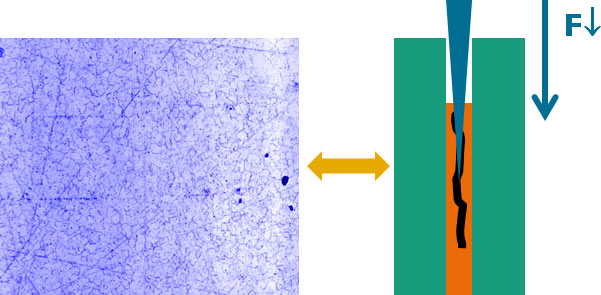

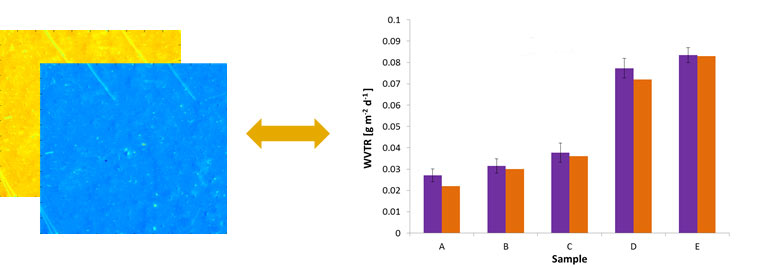

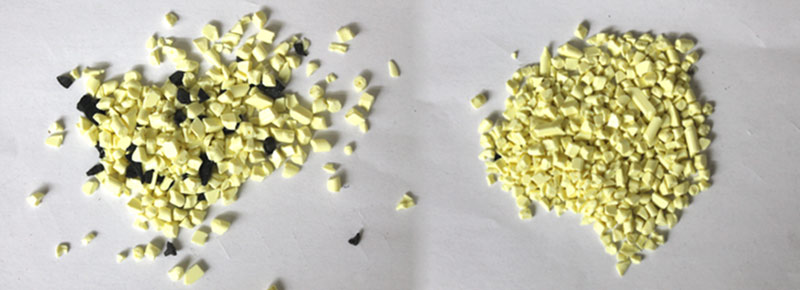

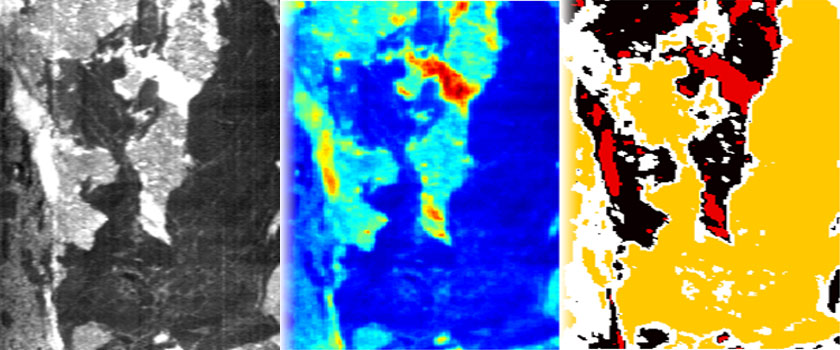

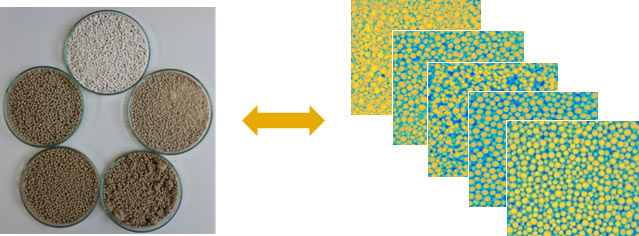

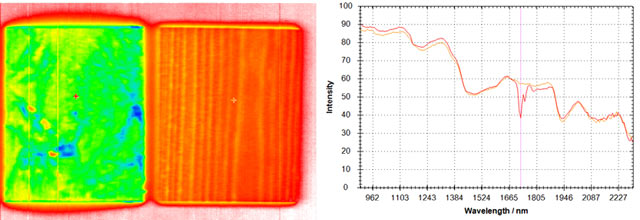

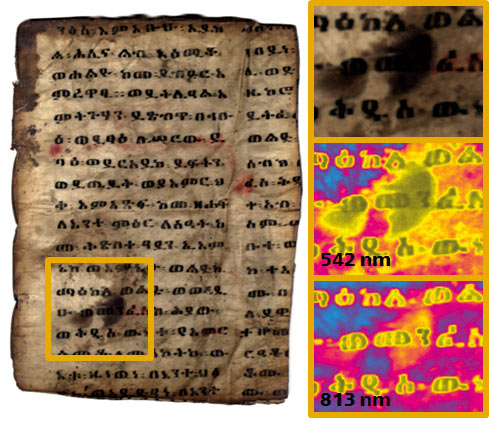

Imanto® provides an ideal platform to develop application- and customer oriented solutions for the spectroscopic and optical imaging technology. Apart from process monitoring systems, stand-alone applications and tailored customer’s solutions can be offered as well.

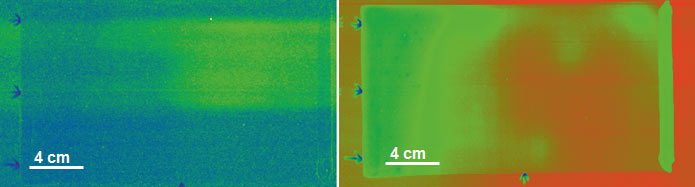

The imanto® platform comprises a unique system of hardware solutions and offers a flexible software platform with the possibility of chemical-statistical evaluation and solutions of your individual demands. The system operates in an on-line as well as in a real-time mode, as required.

Highlights of the imanto® platform

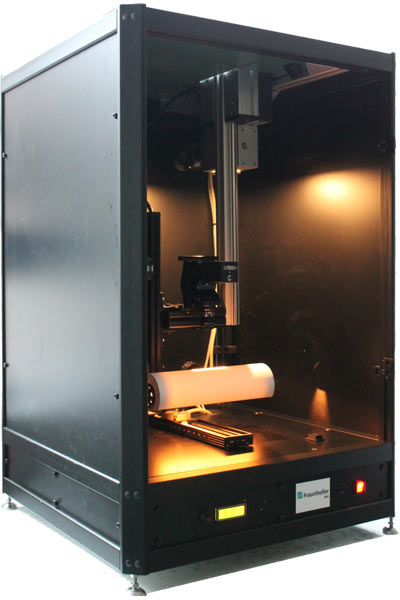

- tabletop system imanto® obsidian

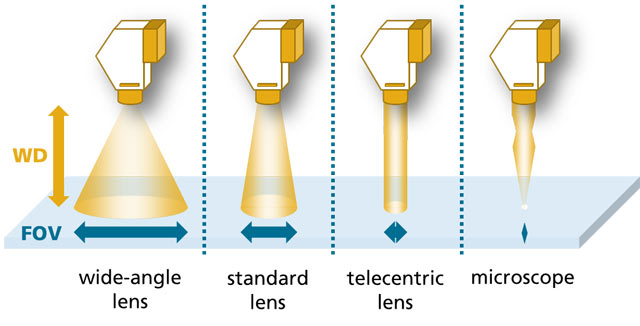

- customized large-scale setups as well as at-line, on-line and in-line process setups

- flexible lighting solutions imanto® lighting

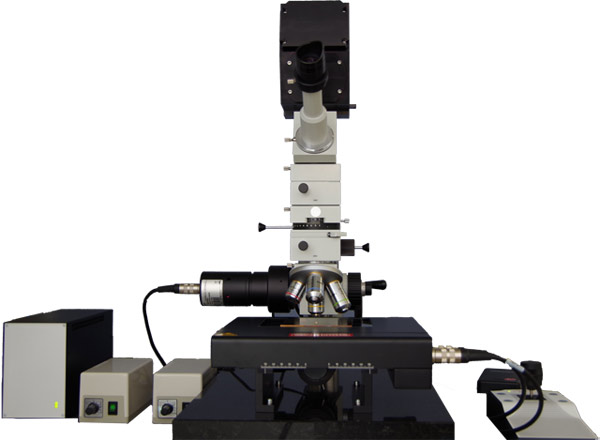

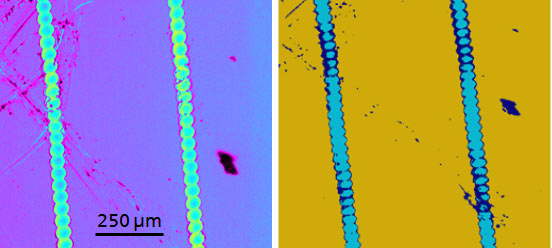

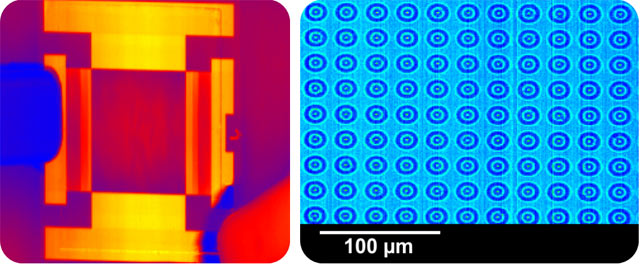

- hyperspectral microscope imaging imanto® microscopy for highest spatial resolution and with the option for near infrared range

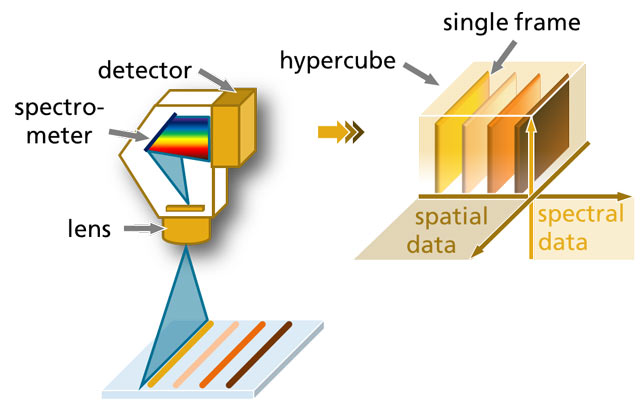

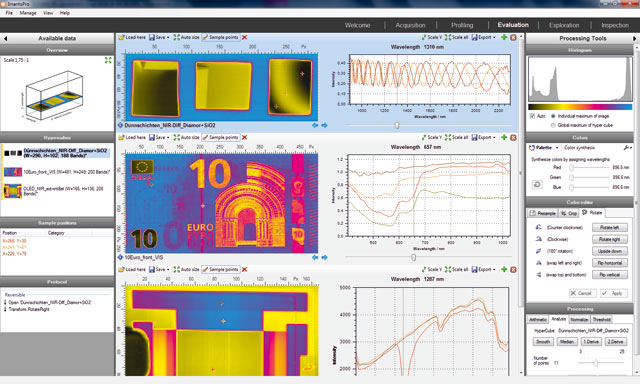

- software package imanto® pro for real-time data processing and evaluation, highly optimized for fastest calculations

Software imanto® viewer

For a closer look on hyperspectral data (i. e. in ENVI format) you can use our free imanto® viewer and our HSI data sets (HyperCubes).

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS