European researcher team is working on a new generation of valuable and more durable organic photovoltaic cells

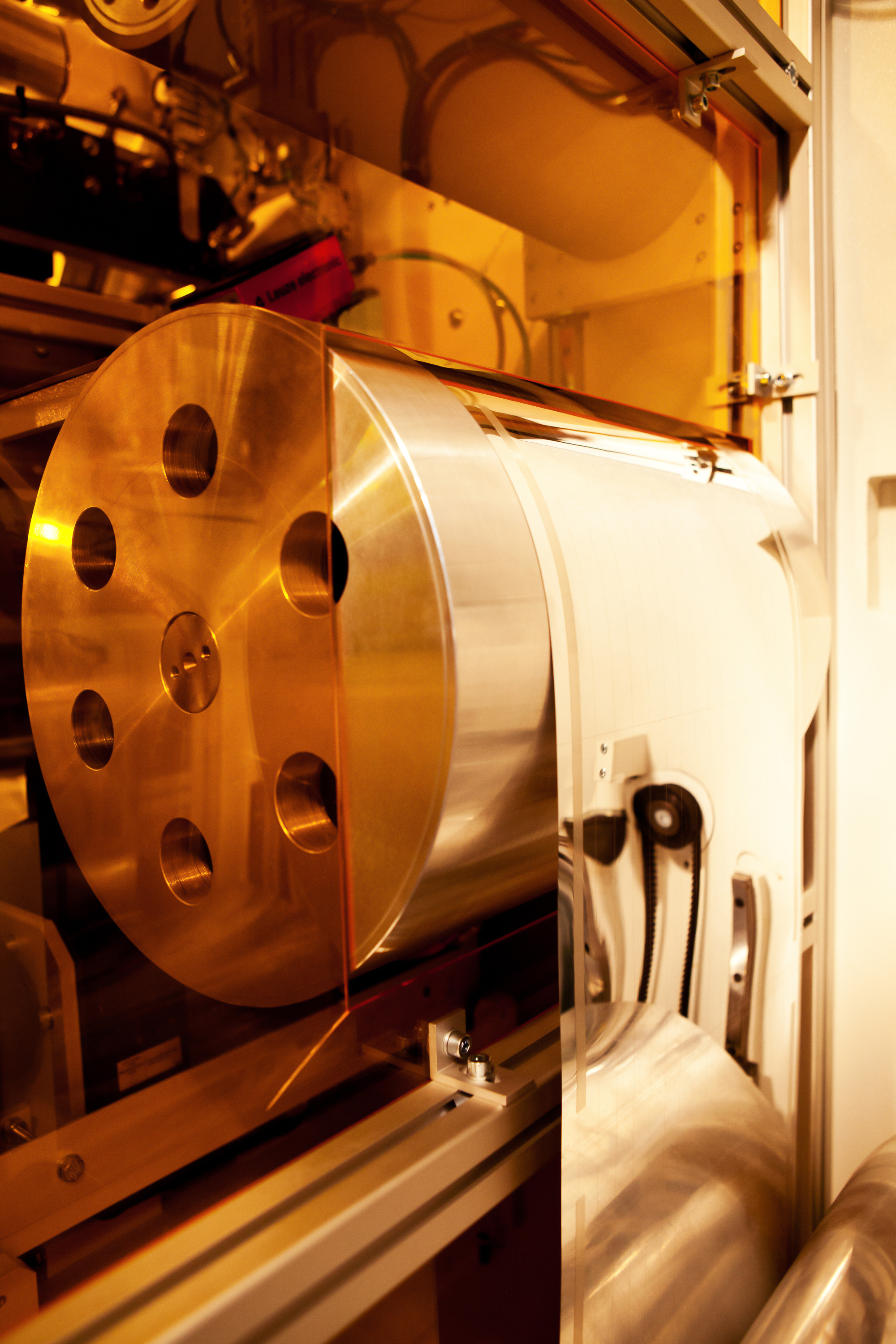

In January 2015 the EU funded project ALABO has started in collaboration with Fraunhofer IWS and Heliatek GmbH, the leading manufacturer of organic solar foils. Goal of the EU project is the cost-efficient production of large-scale, light-weight and flexible photovoltaic foils which are meant to have a clear improved long-term stability.

The advantages of organic solar cells on foil compared to the traditional photovoltaic (PV)-concepts are obvious: the flexible, ultra-light foils are easier to integrate in building structures. Their transparency enables new applications in the glazing and the roll-to-roll procedure allows low cost production with minimal material usage. Furthermore they have a feature that lets them stand out from conventional solar cells. The higher the surrounding temperature is the more efficient is the cell.

“There are still essential technical questions to be answered before organic cells can truly get successful.” says Dr. Udo Klotzbach, coordinator of the ALABO project and director of the area micro technology in Fraunhofer IWS, Dresden. For example, there need to be development of the laser structuring for connecting of the active layers to make the process more gently. „Gently“, explains Dr. Klotzbach, „means in this context, that the waste products of the laser structuring do not harm the active layers and the basic substrate of the cell do not lose the barrier effect against water vapor.

The performance of these transparent barriers is crucial for the lifetime of the PV-cells and therefore is a key parameter of the technology. To guarantee a cell lifetime of 25 years, the barrier needs a water vapor transmission rate of less than 10-4 g m-2 d-1. “This value can be compared with one raindrop per day passing a barrier layer in the size of a football field.” explains Dr. Klotzbach further.

For the first time ever the research team tries to apply a laser structuring process of organic PV-cells on a barrier foil in a monolithic design.

Together with the German company Heliatek GmbH and Fraunhofer IWS Dresden, engineers and scientists from the Dutch HOLST-Centre, the French research Centre CNRS and CEA, the Polish company Sorter and the German company 3D-Micromac AG will work on research tasks in the areas of laser processes, the visual process monitoring and quick evaluation of the barrier performance.

The first meeting of this research project took place on the 23th January 2015 at the Fraunhofer IWS Dresden. The project has duration of 3 years and will be funded with 3.9 Mio. Euros from the EU-program HORIZON 2020.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS