PEGASUS – and it’s running like clockwork!

The development of carbon coatings to minimize friction losses is to remain one of the essential research priorities of the Fraunhofer IWS Dresden for the coming years. Immediately after the completion of the BMWi joint project PEGASUS the follow-up project PEGASUS II starts now. 8 enterprises and 3 Fraunhofer institutes can now advance their research activities with fundings from the BMWi of 20 million euros for the next 39 months.

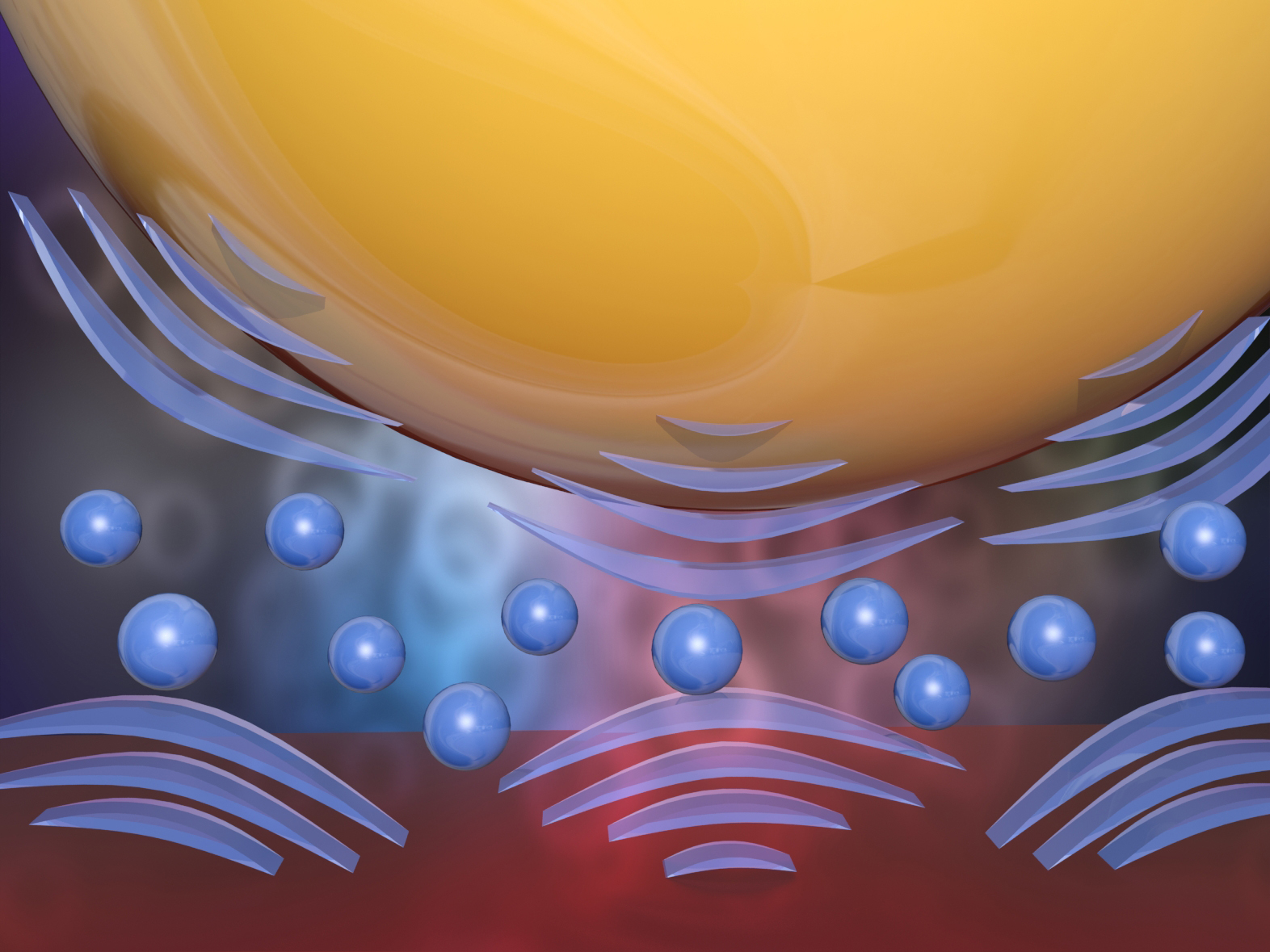

Friction and wear are parameters, which depend on a given material lubricant combination and a variety of stress and environmental conditions. Considering the need for energy efficiency, technical equipment should have the minimum or, even better, no friction at all. This superlubricity parameter has been detected at ta-C carbon coatings produced at Fraunhofer IWS in combination with several organic fluids. “If it is possible to deposit ta-C coatings as constantly stable coatings on sliding components, or to integrate friction-reduced substances into lubricants, tremendous reductions of friction losses will become possible with simple and absolutely environmentally compatible means“, Prof. Dr. Andreas Leson, head of department PVD and Nanotechnology at the Fraunhofer IWS, explains.

The idea of the project PEGASUS was driven by the vision to utilize superlubricity in technical applications. Research focussed on components for the automotive industry such as motors and powertrains. Selected diamond-like carbon coatings and numerous lubricant-additive combinations were investigated in tribological tests, analytical studies and simulations. “Thanks to absolutely identical test conditions for all analysed coating samples, the subsequent comparison of the friction and wear parameters provided comprehensive insight into the systematic influences and conditions for the optimization of the coating process with respect to typical lubricants”, illustrates Dr. Volker Weihnacht, project manager of the IWS sub- project of the PEGASUS group.

The objective of the follow-up PEGASUS II project is to implement the findings to a wide range of technical applications. Thus automotive components in demanding tribological systems are provided with optimized ta-C coatings and tested in combination with selected lubricants. Tests also include hydraulic components which facilitate the application of special fluids and additives. The main priorities of the Fraunhofer IWS within the project consortium are:

- follow-up development with particular respect to improved adhesive strength and reduced surface roughness

- further optimization of the coating technology and the up-scaling of the coating-module with plasma filters to deposit low-defect ta-C coatings

- a variety of tribological and analytical tests to characterize the co-dependent factors.

The Federal Ministry of Economics and Technology will provide the Fraunhofer IWS with 2.047 million euros and the participating industrial partners will contribute further 0.409 million euros.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS