Economical, clean, environment-friendly – Laser wire buildup welding

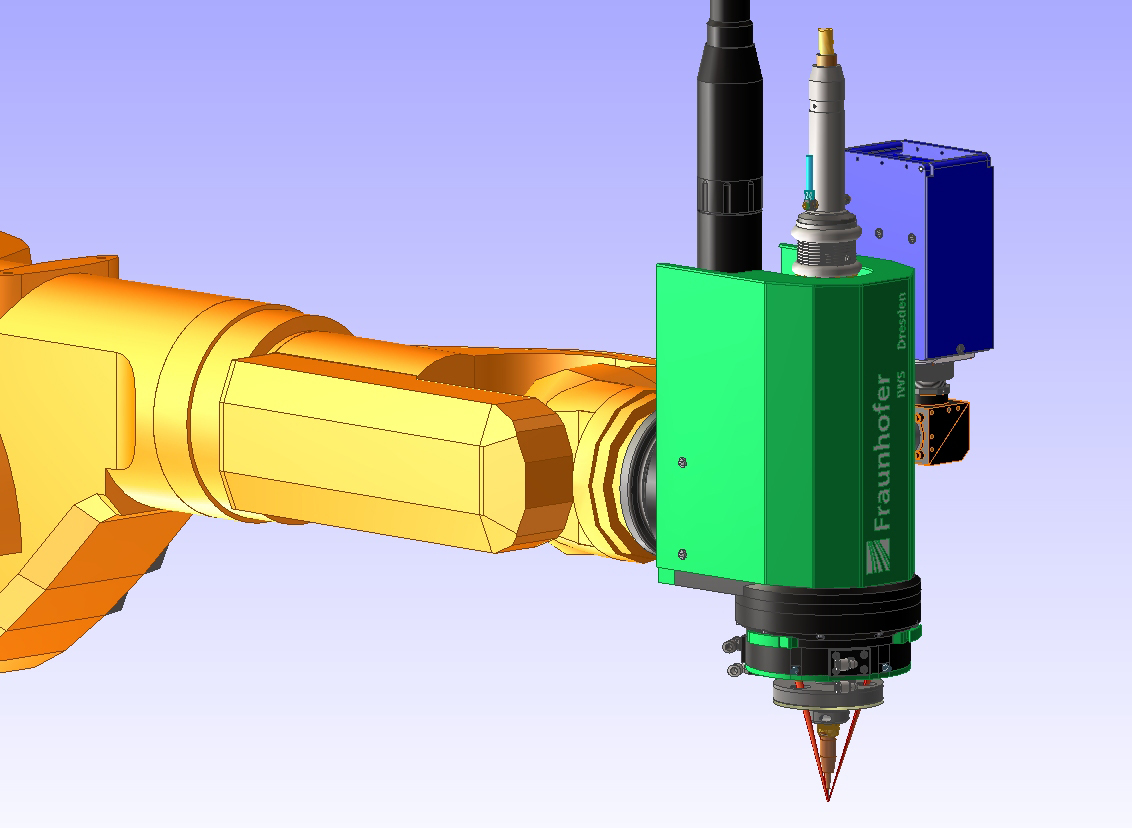

For the very first time the Fraunhofer-Institut für Werkstoff- und Strahltechnik (IWS) Dresden will present its novel coaxial laser wire deposition head COAXwire for high precision metal deposition procedures at the tradeshow Laser World of Photonics 2013 in Munich (hall C2, booth 330). This novel approach is most suitable for the generation and repair of components as well as for the functionalization of surfaces.

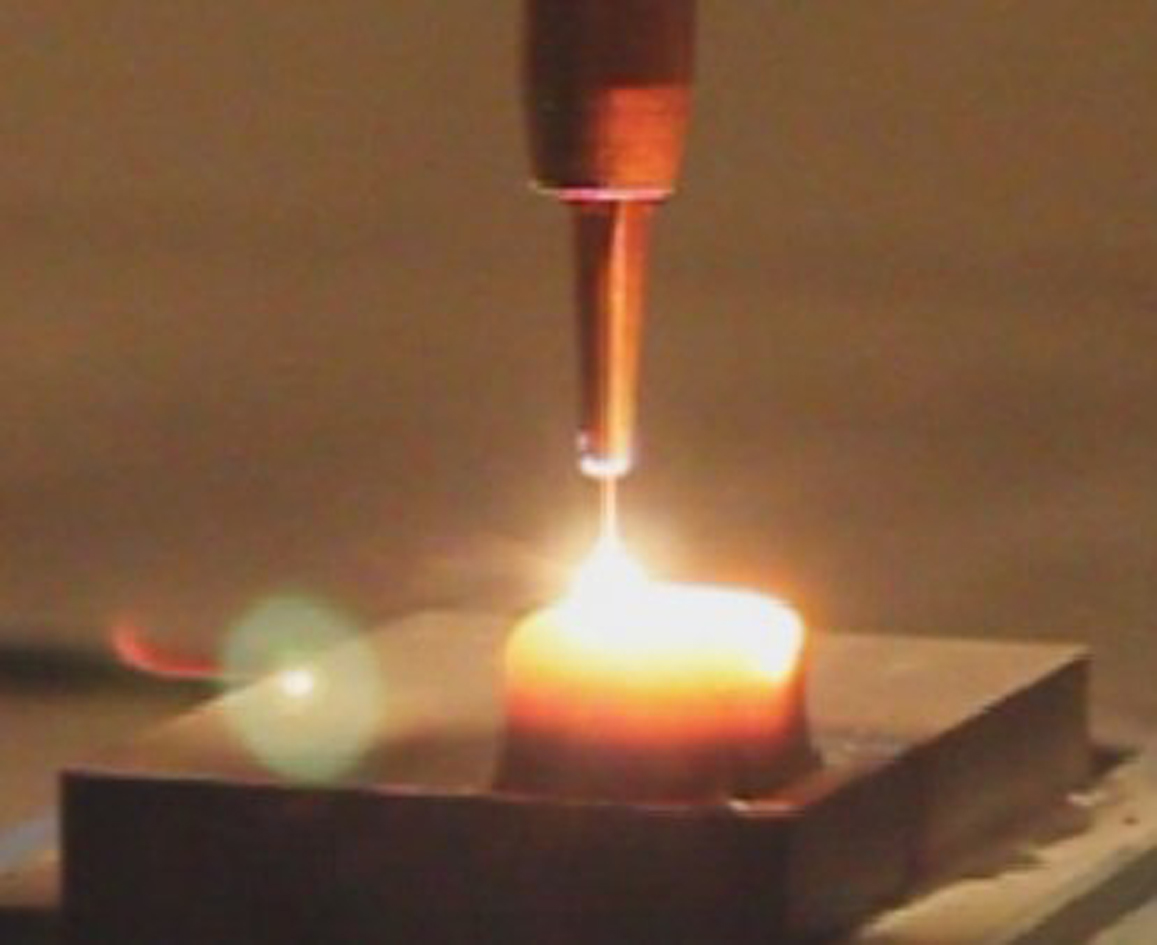

In a form-giving laser buildup welding process the use of wire instead of powder imparts a number of decisive advantages. For example, independent from the part geometry the material utilization is always 100 %. It is a very clean process and there is only a minimal need for finishing steps. Due to the fact that the specific surface of wire is much smaller than that of powder, there is only a small risk that wires will chemically react with the surrounding atmosphere. This property allows very advantageous processing options for reaction-sensitive materials such as titanium or aluminum. These materials can be laser wire buildup welded under normal atmospheric conditions, just with a local inert gas supply.

The novel deposition heads COAXwire are based on a unique optical system for solid-state lasers (rod, disc, fiber) up to powers of 4 kW. The system allows the user to deliver the wire exactly along the center of the laser beam axis and is completely directionally independent. This independence will even be maintained if the welding direction significantly deviates from a down hand position. Wire diameters range from 0.8 to 1.2 mm and indeed, this novel technology is even applicable to wires as thin as 0.3 mm.

In addition to the cold wire version, it is also possible to integrate a hotwire technology into the deposition head to increase the buildup rate. The laser process is efficiently supported by inductive energy, which can be simultaneously coupled into the wire and the component. Thus productivity can be decisively increased. This will mean record deposition rates of 10 kg/h in the field of thermal buildup technology!

The Fraunhofer IWS Dresden is highly recognized for its numerous laser technologies and systems, which have been implemented into industrial applications and are of high economical benefit to our customers. Our scientists and technicians with expertise in laser cutting, welding, cladding, deposition, structuring and surface treatment are looking forward to many interesting discussions at the laser tradeshow.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS