Systems engineering for the processing of nanostructured surfaces

The EU-funded project PLIANT (Process Line Implementation for Applied Surface Nanotechnologies) focuses on the fabrication of aligned carbon nanotubes on electrode surfaces in a roll-to-roll procedure. The high surface, ordered structure and high electrical conductivity of these binder-free electrodes are particularly advantageous, when applied in batteries and capacitors. Increased energy and performance densities directly mirror these advantageous properties. Based on these materials, future high-capacity lithium-sulfur batteries and efficient capaci-tors are being developed.

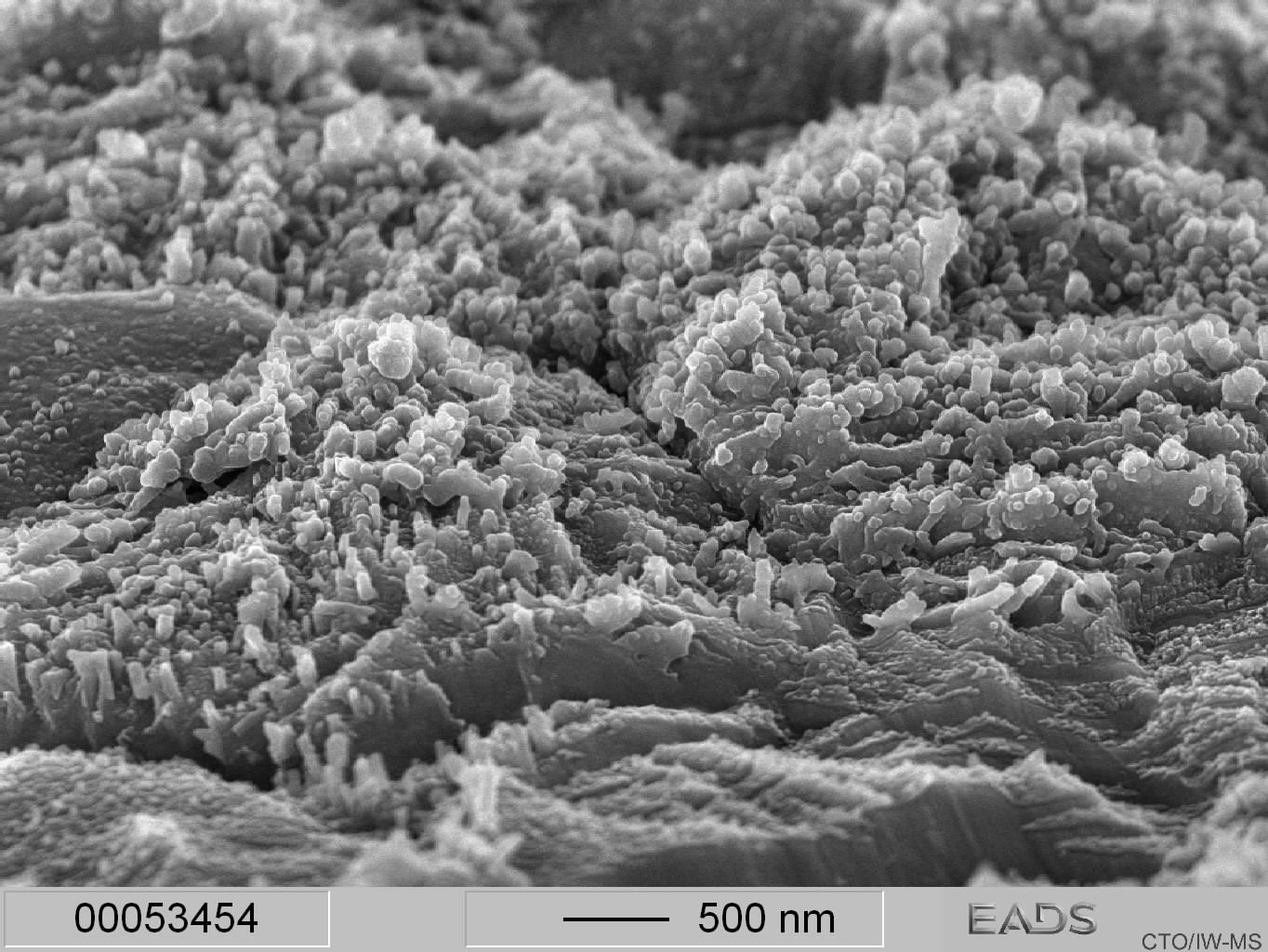

Nanotechnological applications and material selection are characterized by their outstanding diversity. Nanostructures offer unique electrical, optical and mechanical properties, particularly when applied to interfaces and surfaces. Many of these properties and possible applications can already be demonstrated in laboratory. For the step into industrial application, technologies must face the challenge of proving the scalability of material manufacture, at least at a pilot line scale. Furthermore these materials must be tested for their application in products.

On order to take the next step with respect to application and production, a diverse international European consortium cooperates in the joint project. PLIANT started in February 2013 and is funded with 13.4 million Euros. It aims at advancing the European scientific leading position by developing innovative nano and surface technologies. 13 enterprises, 5 research associations and 3 universities, coming from 8 different countries, concentrate their expertise and build a strong research team.

The Fraunhofer-Institut für Werkstoff- und Strahltechnik IWS together with scientists of the Chair of Inorganic Chemistry, TU Dresden coordinate the research. Plant manufacturers and scientists in the field of surface coating technology and process monitoring develop their ambitious aims around three important pillars. As a result, there will be three pilot lines for specific applications in the fields of energy storage, photovoltaics and aviation. Leading manufacturers and developers will contribute their evaluation and specifications.

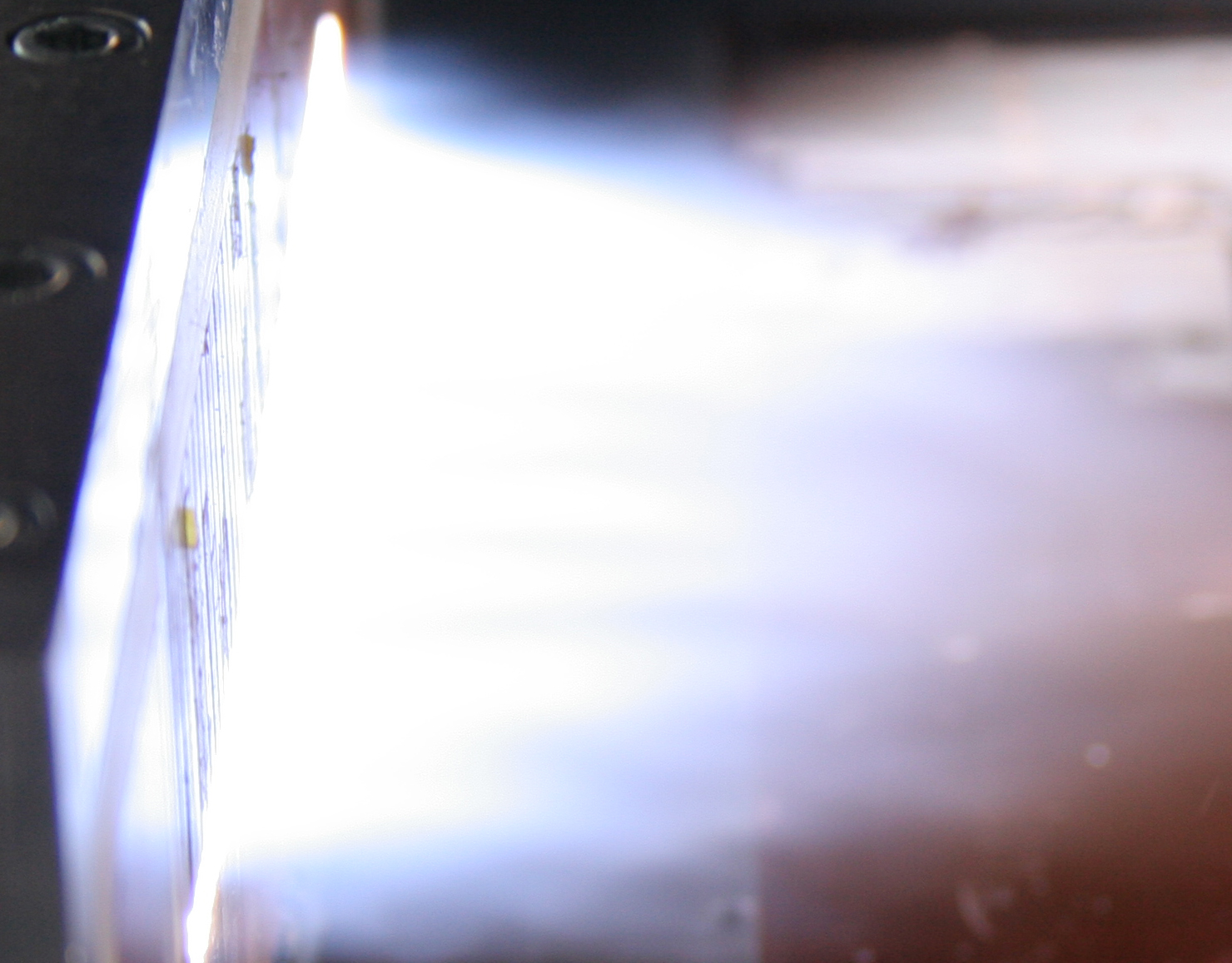

The first pilot line aims at the fabrication of aligned carbon nanotubes on electrode surfaces in a roll-to-roll process. During the second pilot line, nanostructured functional coatings for thin film solar cells will be generated by applying thin film technologies at atmospheric pressure. They are characterized by their highly advantageous performance and low costs. The third pilot line will concentrate on surface pre-treatment processes of lightweight-construction components in aircrafts through atmospheric plasma sources. The resulting nanostructured surfaces should permanently and safely maintain adhesive bondings.

PLIANT is only one example of numerous activities in the field of energy research. From May, 28 – 29, 2013 scientists of the Fraunhofer IWS and the TU Dresden together with speakers of other research associations and industries will present their latest results at the 2nd Dresden Conference “Energy in Future”. 30 talks in 8 sessions and an accompanying exhibition await a vivid exchange of ideas and scientific discussions.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS