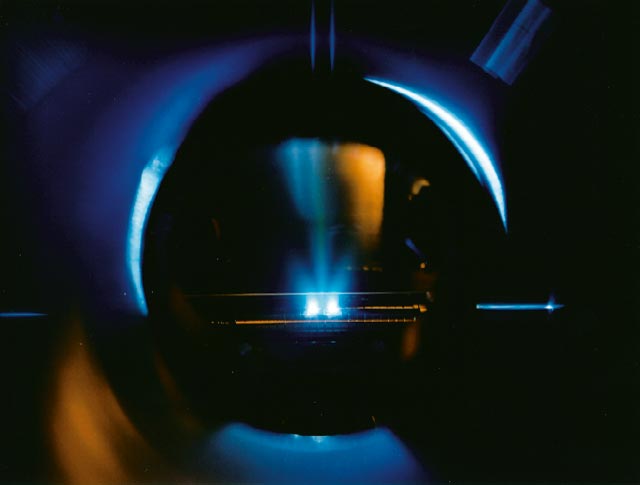

Pulse laser deposition process

Schematic diagram of the target-substrate arrangement for large-area homogenous coating

Layer fabrication

- laser beam focus on the target

- emission of the so-called plasma plume

- condensation of the plasma atoms on the substrate’s surface

Process conditions

- vacuum: p ~ 1...5 x 10-8 mbar

- laser type: Nd:YAG, Excimer

- laser wavelength: 1064 nm, 532 nm, 355 nm, 266 nm, 193 nm

- laser power densities: 107 - 108 W/cm2

Advantages of the PLD procedure

- high mean particle energies -> smooth glass-like amorphous films

- targeted material deposition

- no process gas necessary -> pure layers

- small target size

- basically every material can be used

Applications

- internal coatings of components

- gradient multilayers for parallel or focused x-ray optics (Ni/C, Cr/C, Mo/C, ...)

- monochromatic for X-ray fluorescence analysis

- total internal reflection optics for EUV and X-ray radiation (e.g. ruthenium, platinum, carbon)

- carbon/carbon multilayer systems

- fabrication of layer thickness standards

- substrate smoothening layers

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS